Plug Load Savings of Commercial Foodservice Equipment

Approach

Food service facilities are the largest energy users in the commercial building sector, consuming as much as five times more energy per square foot than any other type of commercial building type. Plug load appliance energy use in restaurants, office buildings, schools, hospitals, and other facilities with foodservice components can be substantial, yet these are rarely included in energy surveys.

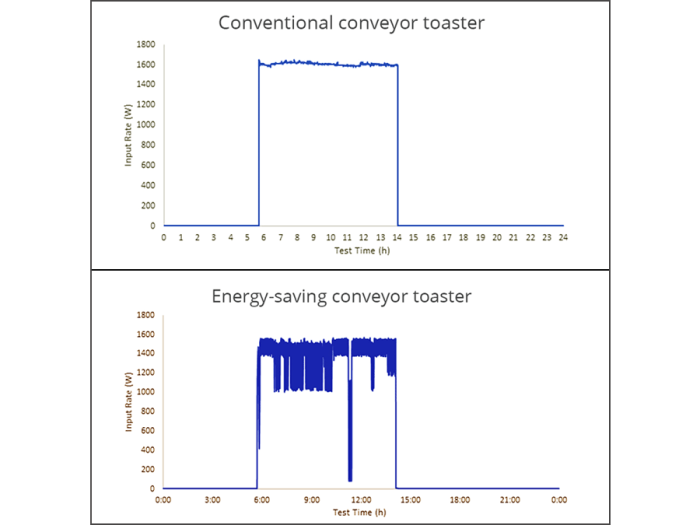

Frontier Energy tested the energy use of 14 categories of countertop appliances operating on a simple 120V plug. Many appliances—toasters, coffee and espresso brewers, soup wells, and rice cookers—are typically on while the restaurant is open to ensure they are ready to make the next order. The team partnered with restaurants, hotels, conference centers, and colleges to monitor energy use of baseline equipment and several variations of new replacement technologies that included smart controls, better insulating materials, advanced heaters, and induction technology.

Results showed that conveyor toasters, soup wells, and holding cabinets had the greatest energy savings. Replacing the baseline conveyor toaster with energy-saving technology demonstrated the greatest payback for the foodservice operator and the utility.

During the study, none of the foodservice operators gave negative feedback about the replacements, most noticed no difference in their day-to-day operation when using conveyor toasters with setback modes, modular holding cabinets, and induction soup warmers, which makes these appliances low risk for replacement.

Frontier Energy:

- Identified foodservice facilities to participate in plug load monitoring and installed data loggers on their existing appliances to create a baseline energy use for each facility.

- Replaced each baseline appliance with a new technology (where applicable), collected energy use data again, and worked with restaurants to understand the effect on food quality or cook time.

- Completed site-by-site detailed analysis of each appliance to understand plug load savings by appliance category.

- Conducted a cost-benefit analysis to identify energy-efficient appliance categories that may need rebates to overcome the increased up-front cost to the operator.

- Wrote a detailed report that is available at www.fishnick.com/cecplug.

Project Team